Deburr Technologies

Design and manufacturing of industrial deburring modules and brushes.

Compact and lightweight deburring module.

Designed for the Aerospace, Medical and Manufacturing industries. This modular unit works standalone or as part of an integrated multiple-unit deburring & finishing configuration.

120VAC, 32 kg.

Patented brushes.

For Titanium, Steel, Aluminum, Wood, Plastic. Specially designed to handle a wide range of material hardnesses while delivering long operating life.

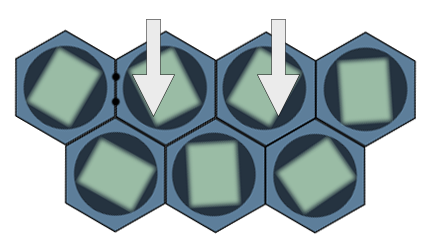

Flexible Deburring Configurations

Each deburring chassis has multiple bolt holes for ease of interconnection to adjacent units. Multiple units can be bolted together to form hexagonal “honeycomb” arrays.

Example 1 : Deburring units on top and bottom and material passes through the middle.

Example 2: Deburring units on the bottom and material passes over the top.

2-axis rotation.

The brush holder and its support both have their own rotating motors that can be independently controlled. This offers an advantage for deburring parts with complex shapes.

Protective Shield.

Protecting the operator from flying debris.

Orientation Options.

Sideways for manual operation

Vertical for automated conveyor deburring

Support Tray.

Adjustable to accommodate different sized objects..

Emergency Stop Button.

High visibility for operator safety.

Dust Exhaust Port.

For connection to a dust collection system.

Speed Control Pedal

Providing the operator with more precise control.

Specialty Brushes

Robotic brush.

Consists of 7 trapezoid shaped abrasive bristles. The brush is designed to facilitate deburring angles and straight surfaces. It is best used with a robotic arm or CNC machine.

Dragonfly brush.

Provides efficient deburring for hollow objects with holes. It consists of two rows of angled abrasive bristles that deburr the inside and outside of a hole. The Dragonfy Brush is best used with handheld rotary tools.